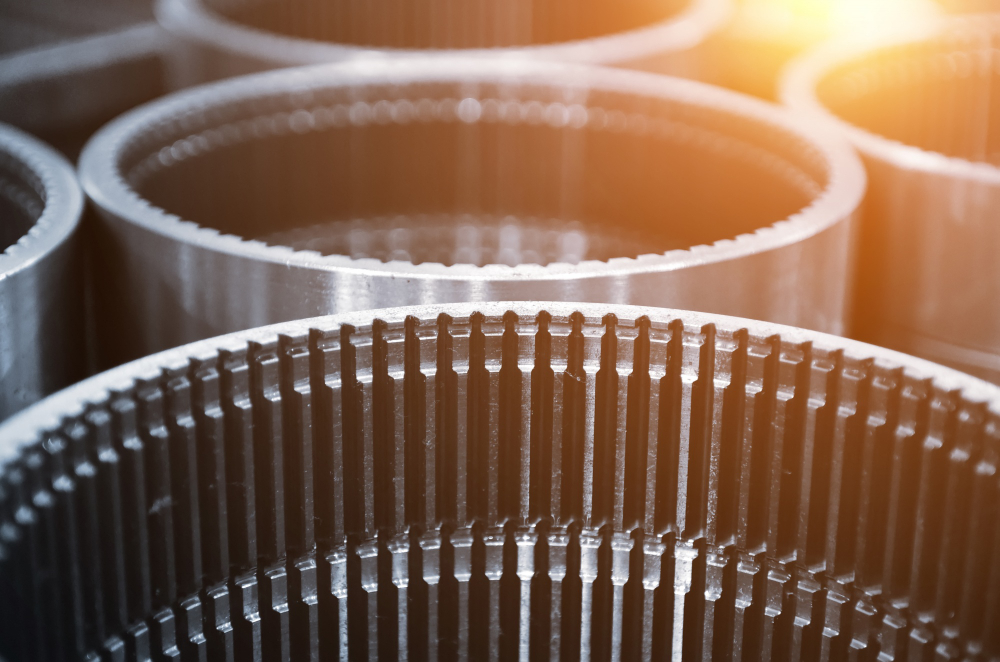

Žíhanie predstavuje kritický proces v materiálovom inžinierstve, zameraný na zlepšenie vlastností a zvýšenie použiteľnosti kovových materiálov. Tento proces, zahŕňajúci ohrev, udržiavanie teploty a kontrolné ochladzovanie, je nevyhnutný pre dosiahnutie požadovanej…